Innovations in Refractory Mixer Machine Design and Performance

The industrial sector has witnessed significant advancements in machinery designed for high-temperature applications, particularly refractory mixer machines. Innovations in design and performance have transformed these machines into highly efficient, reliable, and versatile tools, catering to the evolving needs of industries like steel, cement, glass, and ceramics.

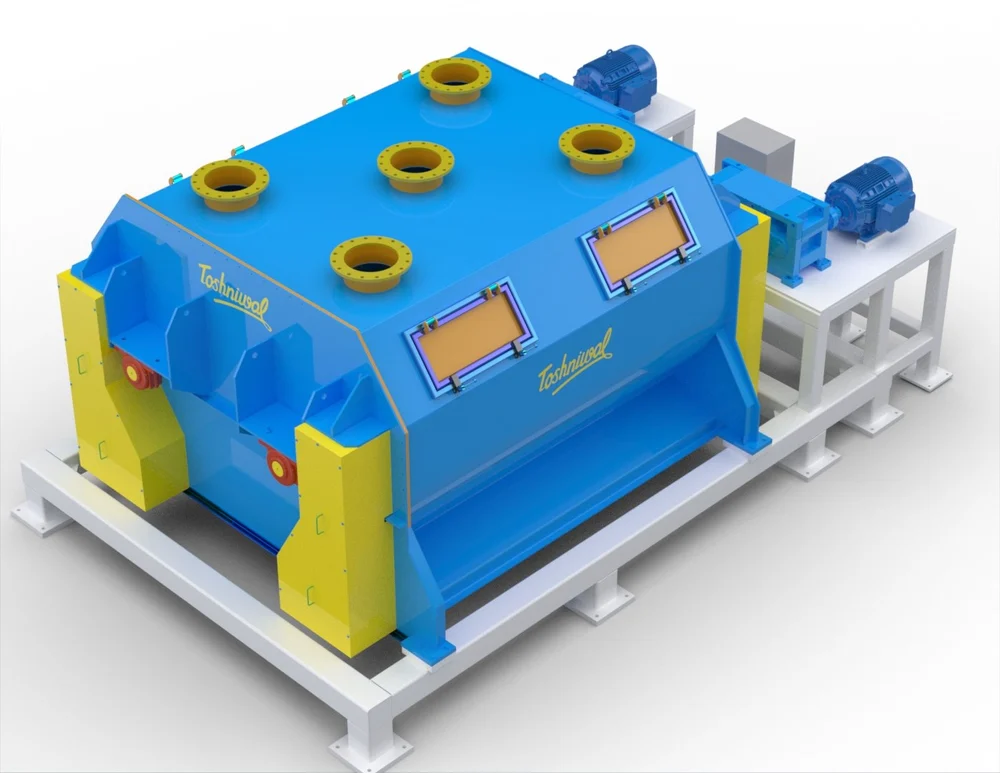

Advanced Mixing Mechanisms

Modern refractory mixer machines incorporate advanced mixing mechanisms to handle a wide range of materials. Paddle mixers, pan mixers, and drum mixers have been enhanced with optimized blade designs and rotation patterns that improve material homogeneity. These innovations reduce mixing time, minimize wear on components, and deliver consistent material quality for demanding industrial processes.

Automation and Smart Controls

Automation is a key area of innovation. Modern refractory mixer machines use programmable logic controllers (PLCs) and intelligent control systems to manage mixing speed, duration, and sequence with high precision. Sensors continuously monitor material load, density, and temperature, making real-time adjustments to maintain optimal conditions. This level of control increases productivity, reduces human error, and ensures consistent results across batches.

Energy Efficiency

Innovative designs have significantly improved the energy efficiency of refractory mixer machines. Efficient motor systems, optimized mixing cycles, and reduced idle times lower power consumption while maintaining high mixing performance. These energy-saving advancements help industries reduce operational costs and meet sustainability goals without compromising productivity.

Durability and Wear Resistance

Refractory materials are abrasive, making durability a critical consideration in machine design. Newer machines use reinforced steel alloys, wear-resistant coatings, and advanced structural designs to withstand harsh operating conditions. These enhancements prolong machine life, reduce maintenance frequency, and minimize downtime, ensuring reliable performance in high-temperature environments.

Material Handling and Workflow Integration

Innovations in material handling have enhanced workflow efficiency. Automated feeding systems accurately measure and introduce materials into the mixing chamber, while advanced discharge mechanisms allow smooth removal of mixed material. These features reduce manual labor, minimize waste, and streamline industrial workflows, contributing to higher operational efficiency.

Versatility and Adaptability

Modern refractory mixer machines are designed to be versatile, capable of handling a wide variety of refractory materials with different densities, moisture contents, and abrasiveness. Adjustable mixing speeds, configurable chamber designs, and modular components allow manufacturers to adapt the machine for multiple applications, from brick production to castable linings and refractory coatings.

Predictive Maintenance and IoT Integration

Cutting-edge innovations include predictive maintenance and IoT-enabled monitoring systems. Sensors track machine performance and provide alerts for potential issues before they cause breakdowns. Real-time data on operational parameters allows engineers to make informed decisions, ensuring optimal performance and extending the machine’s operational lifespan.

Impact on Industrial Performance

The combined effect of these innovations is significant for industries that rely on refractory materials. Improved consistency, faster mixing cycles, reduced energy consumption, and enhanced durability contribute to higher productivity and lower operational costs. Additionally, automated controls and predictive maintenance enhance reliability, safety, and workflow efficiency.

Conclusion

Refractory Mixer Machine has evolved through innovative design and performance improvements, offering unmatched efficiency, precision, and durability for industrial applications. Advanced mixing mechanisms, automation, energy efficiency, and predictive maintenance ensure consistent material quality, streamlined workflows, and long-term reliability. Investing in modern refractory mixer machines empowers industries to meet the demands of high-temperature production with superior performance and cost-effectiveness.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Musica

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness