Computer numerical control is what is meant when people refer to "CNC

Today, we are going to talk about the history that led to the development of modern CNC machining techniques, as well as the capabilities of these techniques and the applications that make use of them. In addition, we are going to talk about the history that led to the development of modern CNC machining techniques.

In particular, we are going to concentrate on the background of the invention of the milling machine and how it came about.

Machining through the use of computer numerical control, also known as CNC machining for short, is a method of production that utilizes a very high level of precision in the operations that it performs. This method of manufacturing is called "CNC machining."Because of the gradual but steady improvements in technological capacities that have taken place over the course of a considerable amount of time, this method of manufacturing is now an option that can be considered as a potential course of action.

CNC machines are electromechanical devices that can manipulate tools around a variable number of axes, typically three or five, with high precision in accordance with the instructions from a computer program. Typical CNC machines have three or five axes, but the number can vary. However, the number of axes can range anywhere from three to five, as is typical for CNC machines. In order for the control code of the machine to be understood, it would first have to be manually punched into a data card, and then the card would have to be fed into a system. Only then would the control code be able to be interpreted. To ensure that the device functions appropriately, it is necessary to carry out the steps outlined in the previous sentence.

In the latter half of the 20th century, technological capability continued to advance, which accelerated the growth of CNC machining technologies. CNC stands for computer numerical control, and it refers to a family of computerized machine tools. CNC is an abbreviation that stands for computer numerical control and refers to a family of computerized machine tools. CNC stands for computer numerical control. Computer numerical control is what is meant by the acronym CNC.

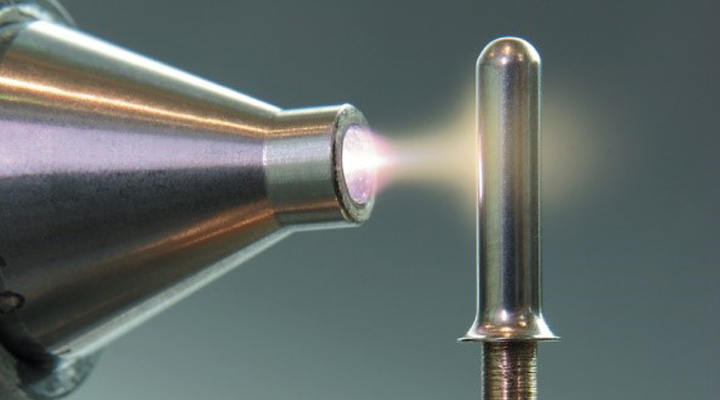

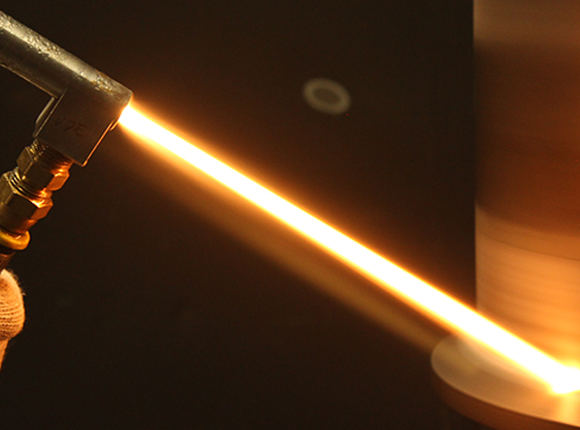

The procedure of subtractive milling, which was only made possible by the introduction of computer numerical control manufacturing (CNC).

Additive manufacturing, which is also known as 3D printing, is a process that is an additional method that engineers or manufacturers can use to create a physical part from a computer-aided design (CAD) file. The CAD file is used as the starting point for the additive manufacturing process. This process is also referred to as printing in three dimensions in some circles.

The two distinct ways of thinking that are being contrasted with one another in this passage couldn't possibly be any more dissimilar to one another if they tried. This passage is a great example of how two different ways of thinking can be so drastically different from one another. Machining is a subtractive process, which means that during the process, material is removed from a stock. This removal of material is what defines machining as a subtractive process. Machining is considered a subtractive process because it involves the removal of material during the process. Because of this, some of the available material will be reduced. This term refers to the process of machining using computer numerical control, more commonly referred to as CNC, in addition to other types of machining.

A Focus on the Capabilities of Computer Numerical Controlled EquipmentOver CADEquipment

Machining is the process of creating a finished product or component from a stock piece of material, such as aluminum, steel, or titanium. The finished product or component can then be sold or used. In order to get started, the material is used in its raw, unprocessed state as the starting point. When everything is put together, the final result might be the finished product itself, or it might be a component of the finished product.

Machinists were required to manually write the G-code that controlled CNC machines before modern computer-aided manufacturing and computer-aided design programs like Autodesk's Fusion 360 were made available to the public. Users no longer need to manually program the device because this has been eliminated as a requirement.

When the capabilities of automated CNC machining are compared to those of manual alternatives, such as lathes and other machining techniques, the benefits of utilizing CNC machining, which is also known as computer numerical control, can begin to be seen. This is because CNC machining is also known as computer numerical control. Computer numerical control is another name for CNC machining, which is what CNC stands for. The process of carrying out operations by means of computer numerical control is referred to as "CNC machining," and the term refers to the process itself.

The output of CNC machines is capable of maintaining a higher level of precision and accuracy despite being produced at a significantly higher speed than that of conventional machines. This is made possible by the use of computer numerical control (CNC) technology.

The tolerances that can typically be provided on parts by using standard machining fall somewhere in the range of plus or minus 0 on either end of the spectrum. Alternatively stated:

It is possible to achieve tolerances of approximately plus or minus 0 by making use of the processes and techniques involved in fine machining. This can be accomplished by using these methods.

Polishing is one of these specialized processes, and it has the potential to offer repeatable tolerances that are as precise as 0.00 plus or minus. This precision can be achieved through the use of repeatable measurements.

To put this into perspective, the average width of a human hair is somewhere in the neighborhood of 0.1 millimeters.

An Explanation of the Numerous Distinct Groupings of CNC Machines and the Tasks That Can Be Completed by Each and Every One of Them

Since we have already gone over the fundamentals of CNC machining, we are now in a position to move on to the next step of the process, which is to investigate the more advanced aspects of the technique. This will allow us to complete the process. There is a huge variety of different designs and specialized machining processes, all of which require the use of a variety of different cutting tools in order to be carried out successfully in order for them to be carried out successfully. There is no one piece of equipment that can perform all of the tasks that need to be done, and there never has been and there never will be.

In order to fulfill this requirement, machinists will frequently produce digital tool libraries that are capable of communicating with the actual CNC machine. The cost of one of these machines can range anywhere from zero to several hundred thousand dollars, depending on the particular model that is purchased.

CNC Machines that are mobile not only along a three-axis plane, but also along a five-axis plane in addition to the three-axis plane in addition to the three-axis plane.

When performing fundamental CNC machining operations, the operator will need to move along the X-axis and the Y-axis, respectively. Both of these axes are referred to as moving axes.5 axes, 3 axes, or 5 axes.

You might be able to picture that the possibilities that can be accomplished with 5-axis machines are very close to being limitless. This is because 5-axis machines have so many moving parts. This is due to the fact that they have an unusually high number of axes of movement at their disposal. This peculiar behavior can be traced back to the fact that each of these machines possesses five axes of movement, which is the primary factor responsible for it.

Once upon a time, 5-axis machines were only used for jobs that required a high level of precision; however, as their price has come down, more and more shops are beginning to adopt them as standard equipment. This is due to the fact that their versatility allows them to be used for a wide variety of applications. This is because of the adaptability that they possess, which enables them to be utilized for a great deal of different kinds of tasks. Referenced in the following works:

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness